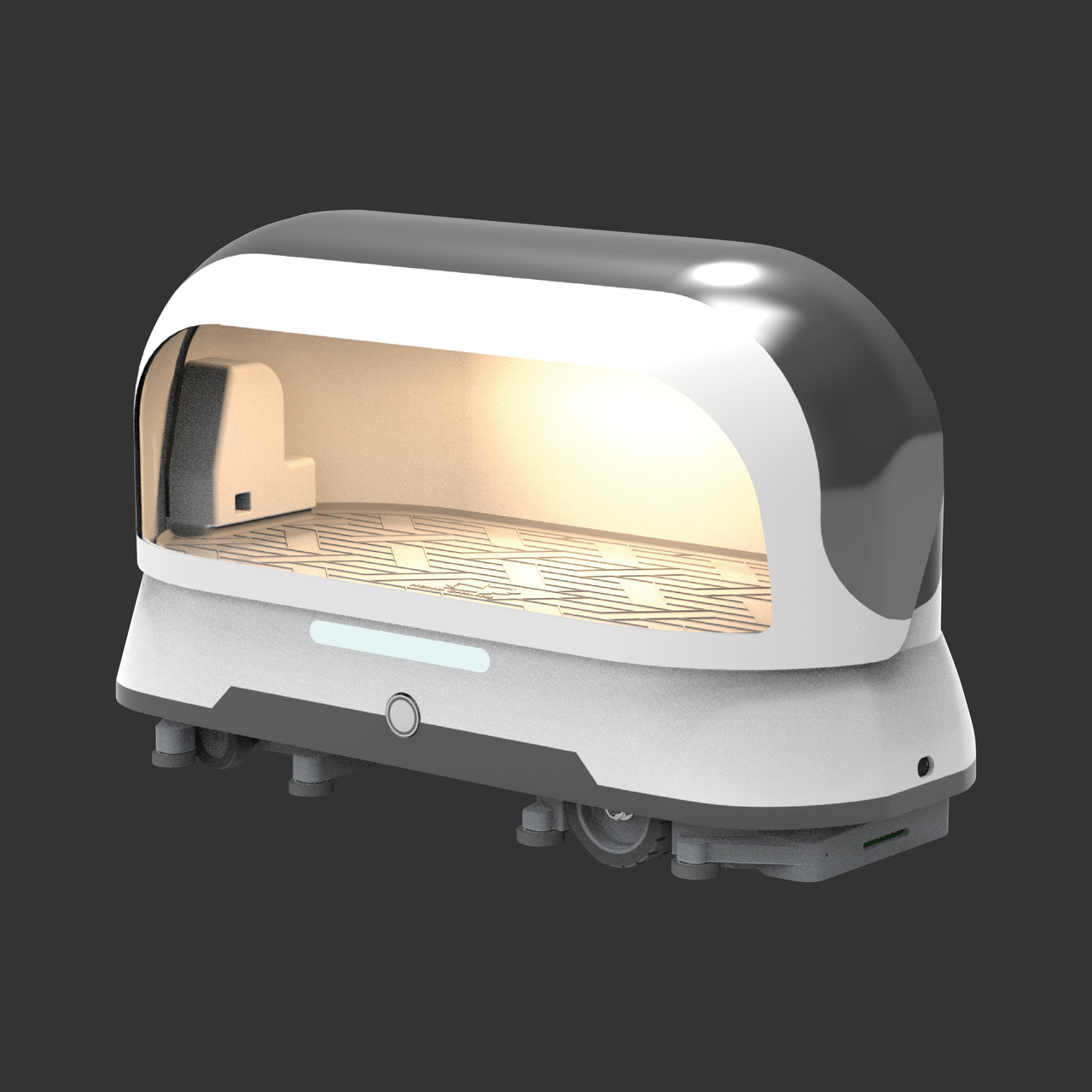

Food Delivery Robot (Bullet Train) - FreshCover Food Delivery Robot - Series P

- Automated Robots (Cooking, Serving, Cleaning, etc.)

- Renovation, Remodeling

- Opening Support, Consulting, Franchising

- Design Refurbishment / Opening Support Others

- Interior (Hotel Common Areas / Food Service / Meal Service) Others

- Robots (for serving, delivery, cleaning, guidance, security, etc.)

- Technology (Robot / AI / RPA) Others

- Meal Management Systems (nutrition, meal service , menu support, billing, etc.)

- Technology (Meal Service related) Others

- Employee Satisfaction Improvement, Work Style Reform

- HR Solution / Recruiting / Improving Employee Satisfaction Others

-

Target Sector

⋆Business formats such as conveyor-belt sushi and belt-type restaurants where temperature control and hygiene management are critical

⋆Restaurants with long distances between tables, where labor shortages make the delivery workload heavy

⋆Brands seeking to strengthen hygiene measures, including droplet prevention and protection against foreign object contamination

⋆Foodservice outlets that frequently serve set menus and multiple plates simultaneously

⋆Restaurants aiming to shorten staff movement lines and improve operational efficiency

⋆Companies looking to reduce staffing needs in the back-of-house

⋆Brands that require both strict hygiene management and high operational efficiency -

Usage Scenes(Usage/Recipies)

⋆Hygienic serving with Fresh Cover for food items where droplet and contact risks must be minimized

⋆Safe delivery of temperature-sensitive menu items such as ramen, rice bowls, soups, and set meals

⋆Large-floor restaurants where staff spend significant time on long-distance food delivery

⋆Simultaneous delivery of multiple orders by utilizing the dual-section carrier

⋆Improving peak-time efficiency in operations run by a small number of staff

⋆Store layouts where guest seating is dispersed and it is difficult for staff to move smoothly through the aisles -

Specialities,Sales point

1.Hygienic serving with Fresh Cover

⋆Equipped with a lid that helps prevent droplets, dust, and foreign object contamination

⋆Enhances food safety and overall hygiene management

⋆Delivers dishes in a stable, consistent condition regardless of in-store environment

2.Dual-section carrier structure for simultaneous delivery

⋆Car body divided into front and rear sections

⋆Enables simultaneous delivery of main course and soup, set menus, or orders for different tables

⋆Greatly improves serving efficiency during peak hours

3.Simple, user-friendly operation

⋆Intuitive design that allows any staff member to operate it quickly

⋆Reduces staff walking distance and supports labor-saving operations

4.Compact and lightweight, suited to a wide range of formats

⋆Can be installed even in locations with limited space

⋆Ideal for cafés, ramen shops, Chinese restaurants, and fast-casual concepts - Countries of Trade

JAPAN : Both direct and indirect transactions are acceptable

| Size / capacity | (Pro ver.) Robot dimensions: 418 (W) × 177 (D) × 248 (H) mm Robot weight: 5.2 kg Maximum payload: < 2 kg Load size: 320 (W) × 150 (D) × 120 (H) mm Maximum speed: 60 m/min (SE & Lite ver.) Robot dimensions: 878 (W) × 178 (D) × 250 (H) mm Robot weight: 8 kg (2 units combined) Maximum payload: < 2 kg per unit / < 4 kg total Load size: 370 (W) × 270 (D) × 120 (H) mm per unit Maximum speed: 78 m/min |

|---|

Hong Chiang Technology

https://www.hong-chiang.com.tw/ja/index.html- Overseas exhibitors

- Exportable

- HCJ 2026

- Food Service Equipment

- Booth number E4-V03

| Exhibited products | Food serving robot,Food serving system,Serving system,delivery robot,Automatic food serving system,Automated food serving system,Automated serving robot,Automated food delivery system |

|---|